There are news reports of an outbreak caused by a novel coronavirus (2019-nCoV) that seems to have originated in Wuhan, China. Cases of coronavirus are being reported around the world resulting from travel to and from the province. The virus causes flu-like symptoms and has proven fatal in some cases.

The CDC recommends if you are infected “to wear a Surgical Face Mask when in the same room as other people” or “if this is not possible that others in the same room should” wear face masks. As a result, there is a sudden and dramatic increase in the demand for surgical face protection. The typical face mask is made with melt blown polypropylene media.

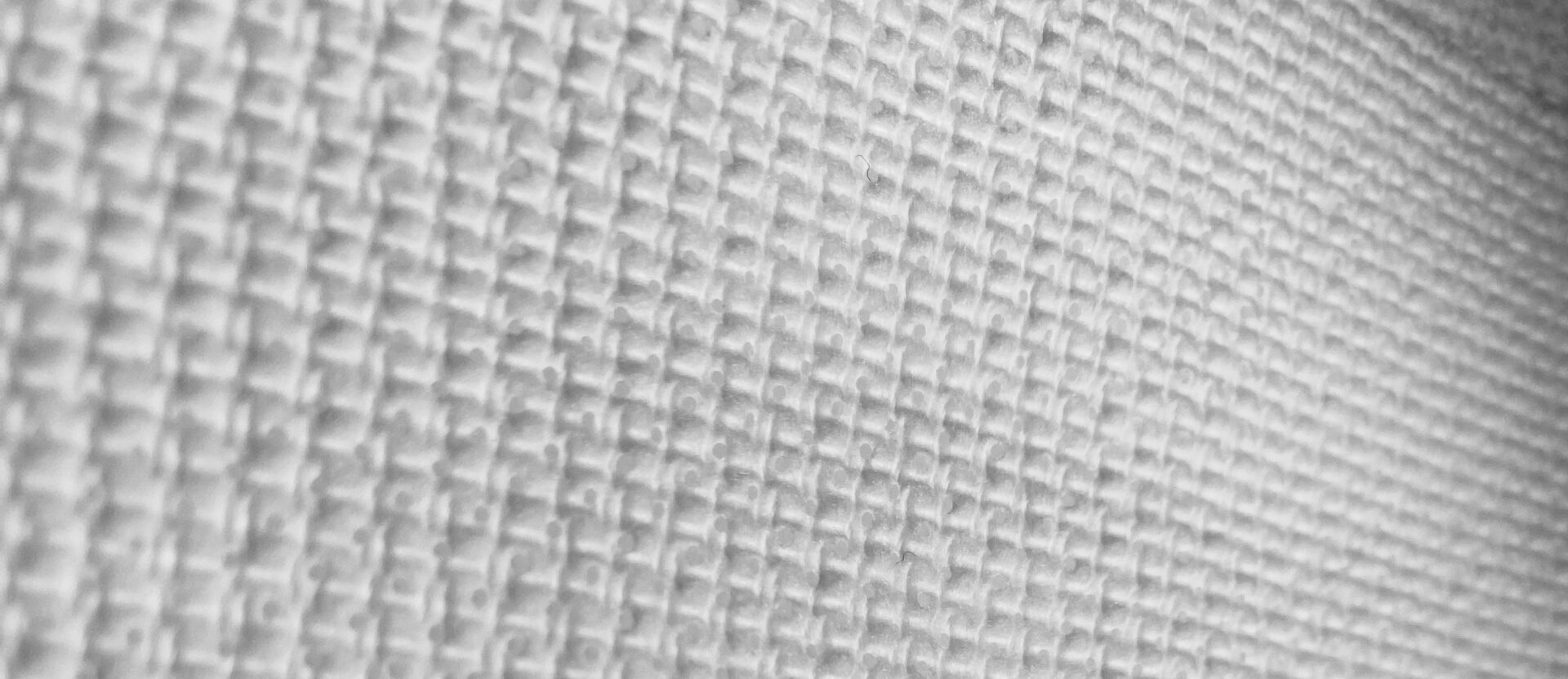

Monadnock Non-Wovens LLC has already established and validated a portfolio of air filtration media with various weights of polypropylene non-woven from 10 to 34 gsm with exceptionally low air resistance to meet this new global challenge.

Monadnock has a firmly established surgical face mask business supplying qualified roll goods to converters and producers of medical face masks for the dental and hospital markets. The key is to produce consistent media with a suitable combination of filtration and breathability that is easy to process and convert into a variety of face mask configurations. A standard test is the Bacterial Filtration Efficiency test (BFE).

In combination with other non-wovens, these products meet the F 1862 standard for low, moderate, and high resistance to synthetic blood penetration and particle retention — typically 95%, 99%, or better than 99% efficiency. Monadnock uses NIOSH Respirator Test Protocols to qualify the media including critical solid particle challenges. Products made with Monadnock’s face mask media meet the most rigorous BFE requirements.

The Monadnock range of medical face mask media has been developed over 20 years and now includes a family of roll goods to meet most market requirements including the fast-growing consumer or home market. Especially developed production machines provide slit rolls typically in the 170mm-200mm (nominally 6 ¾”-7 ½”) size. Typically large master rolls are provided and converted into masks which are then sold separately or in packs.

Contact Keith Hayward, Managing Director, (570) 839-9210, for more information.