Pilot to Production Program

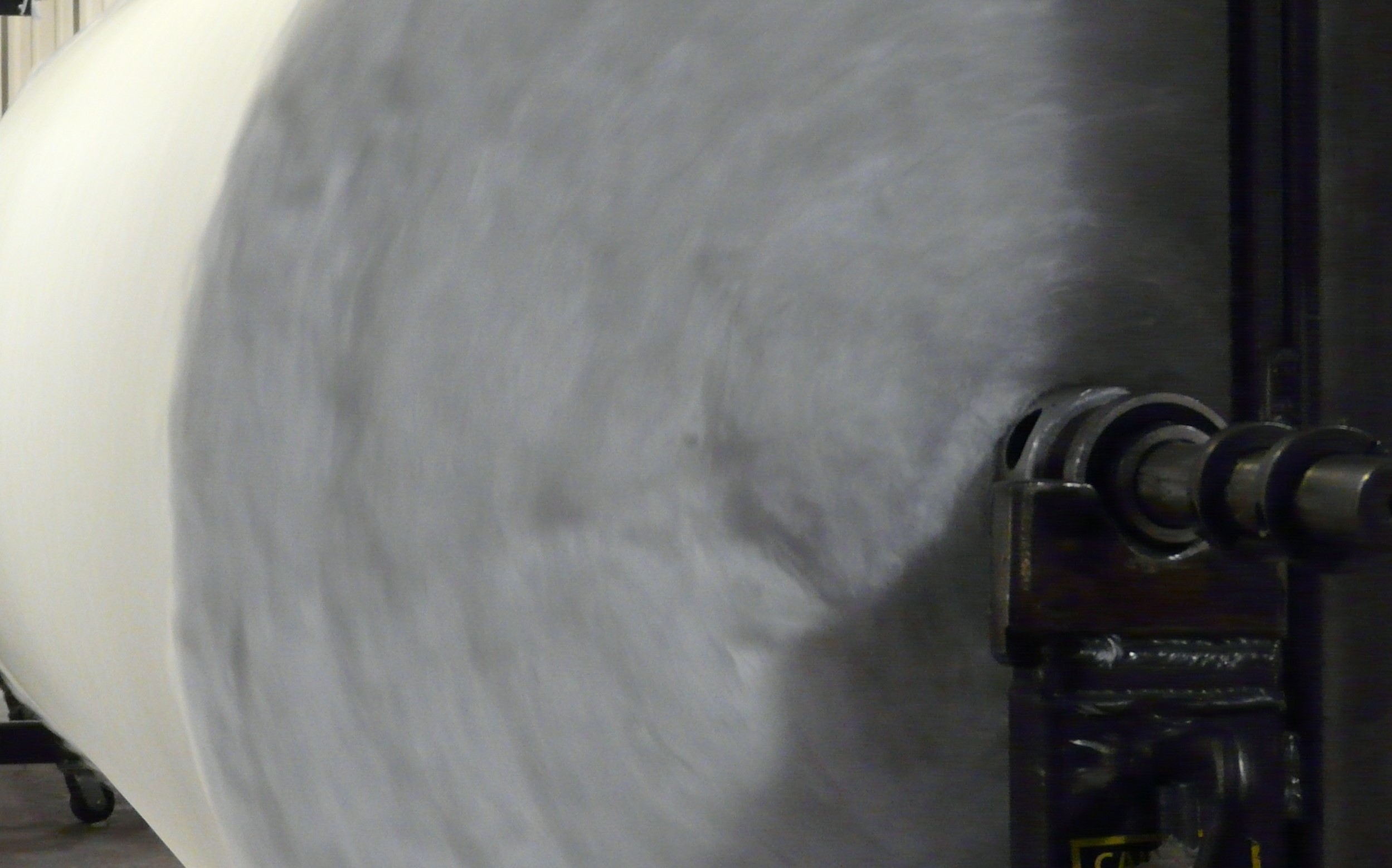

At Monadnock Non-Wovens LLC, we understand that the journey from innovative ideas to industrial-scale manufacturing can be a significant leap for product developers, especially in the realm of fine fiber melt-blown polypropylene. That’s why we proudly introduce our “Pilot to Production” program—a tailored solution designed to bridge the gap between R+D scale production and full-fledged industrial manufacturing.

Unlocking Innovation

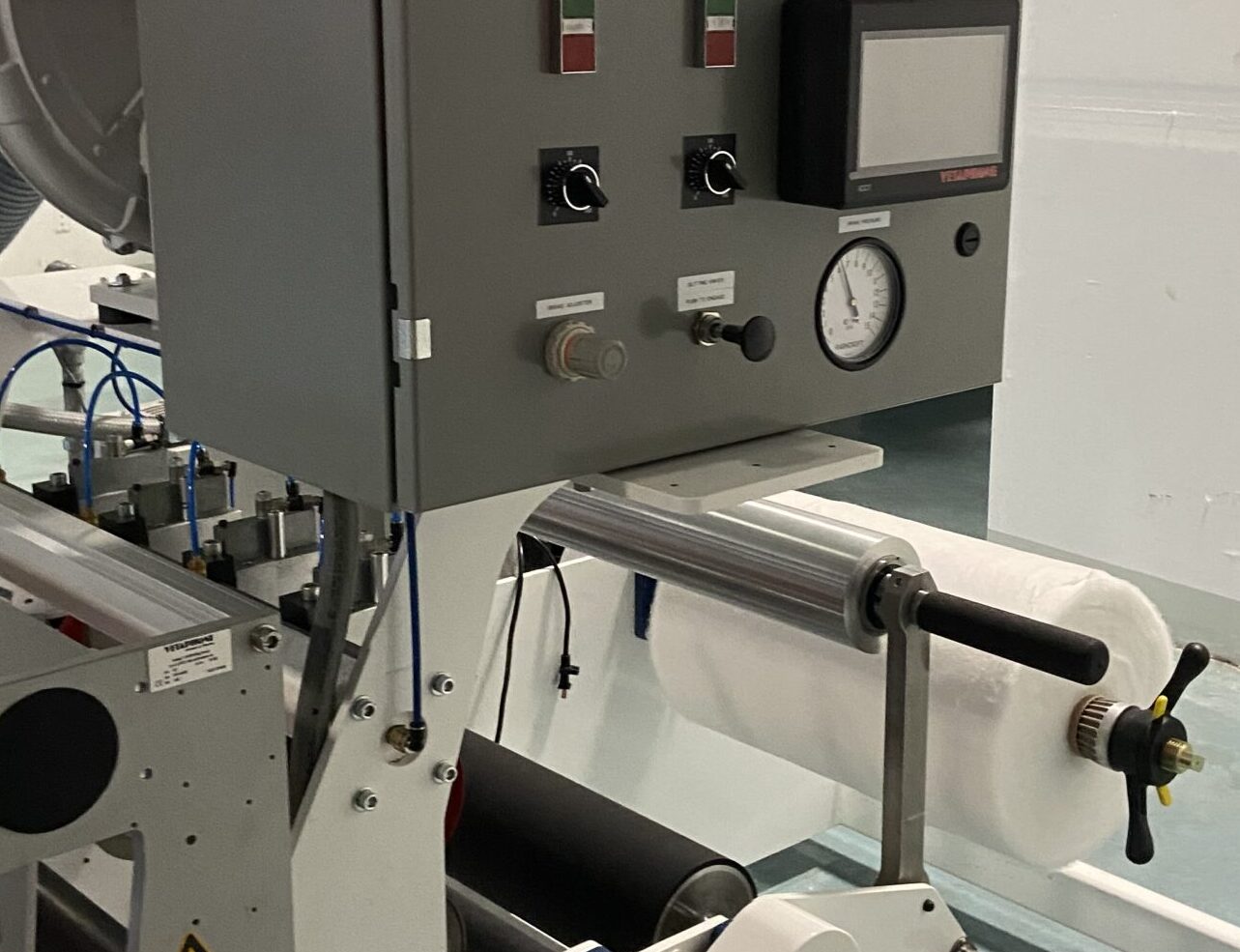

For developers with groundbreaking concepts in media or composites, transitioning to industrial-scale production can be a daunting task. Monadnock’s experienced team and right-sized melt-blown and calendering machines serve as invaluable assets during this pivotal phase. We offer you the benefit of a fully equipped applications product development laboratory to ensure that the design of new products and materials will work.

Versatile Applications

Our “Pilot to Production” program caters to product developers exploring characteristics or special properties within the rapidly growing allergen barrier, anti-microbial, or odor removal applications. These innovations find applications in fabric, homeland security, medical devices, and select consumer products.

From Prototype to Reality

Monadnock Non-Wovens boasts expertise in navigating the transition from prototype to industrial-scale production. Whether it’s polypropylene melt-blown with or without various additives and combined materials, our company’s size and flexibility enable cost-effective and rapid development of roll goods media suitable for further conversion or direct sale.

A Ready-Made Home for Success

Once approved by the market, clients gain access to a well-established home for subsequent production, complete with established processes and cost structures supported by an ISO9001 Quality System. Our Pilot programs may include renting machine time, toll converting, or conventional purchase, providing a range of options tailored to your specific needs.