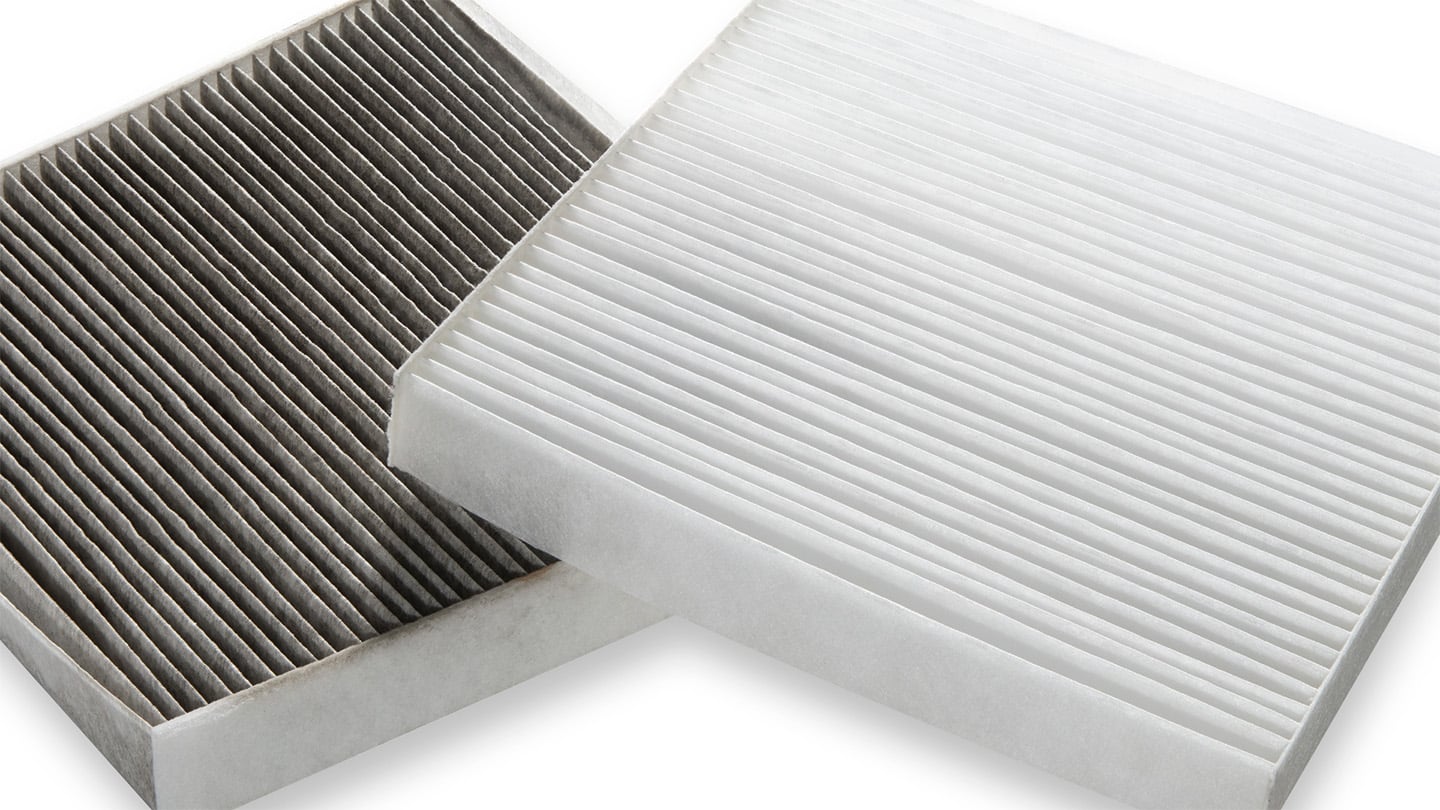

Introducing the next generation of sound attenuation media.

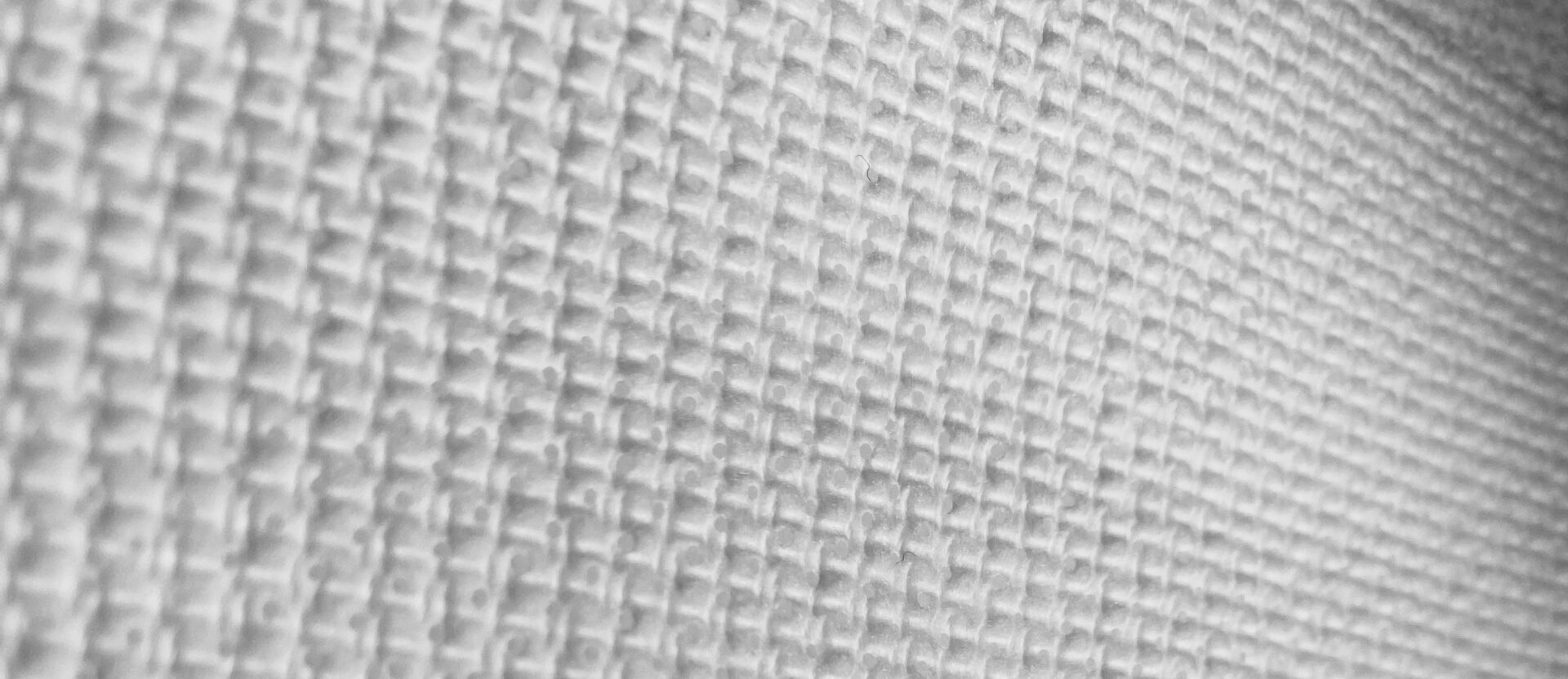

Leveraging its manufacturing experience and long history of partnership with the automotive industry, MNW has designed and developed a product that significantly improves sound absorption at lower frequencies through an improved fiber matrix and a tunable scrim on both sides.

With this tunable scrim, Monadnock HPAM (High Performance Acoustic Media) provides excellent sound absorption at low weight allowing vehicles to meet acoustical targets while addressing challenges of light-weight aluminum bodies and improved acoustics. This new product is compressible allowing for use in cavities with varying thickness. HPAM may be die cut with existing equipment – no tooling or equipment modifications are necessary. Factory die cut parts have a perimeter seal to encapsulate loose fibers. MNW has also developed special packaging to maintain the integrity of the product in transit.

“We are pleased that new HPAM is already approved for use at GM and Ford plants,” said Monadnock Managing Director Keith Hayward. “This innovative media development offers the quiet ride and fuel efficiency that the market is seeking and that the consumer demands.”

As with all MNW products, HPAM is made with 100 percent renewable electricity through the purchase of Green-e certified renewable wind power energy certificates. Constructed with 100 percent virgin polypropylene, HPAM is lighter than competitive products – critical for fuel economy, and it is fully recyclable at the end of its useful life. For more information about Monadnock Non-Wovens send us a note.