HPAM®

High Performance Acoustic Media

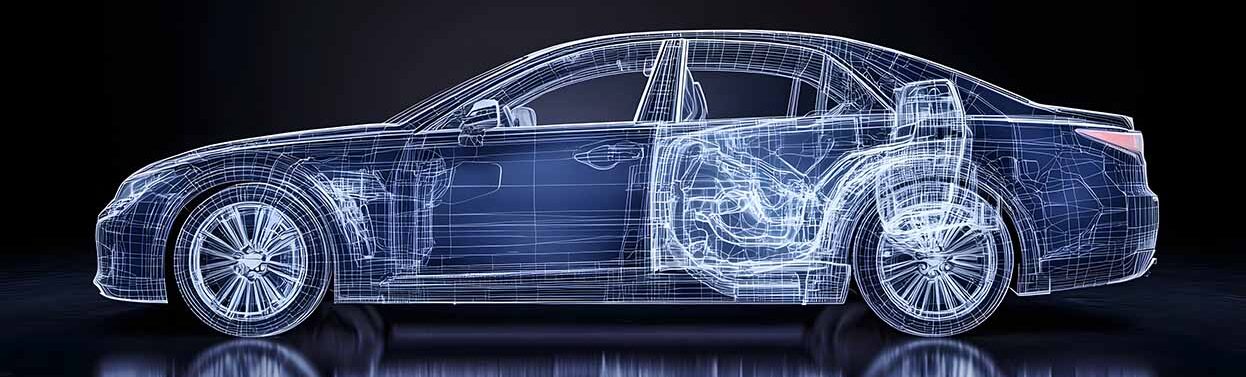

The next generation of sound attenuation media for the automotive market.

HPAM High Performance Acoustic media is a nonwoven NVH (noise, vibration and harshness) insulation solution offering improved sound absorption at lower frequencies in all types of appliances, automobiles and even large trucks and farm vehicles.

HPAM media significantly improves sound absorption at lower frequencies through an enhanced fiber matrix and a tunable scrim on both sides. With this tunable scrim (top and bottom facing layers), Monadnock HPAM provides excellent sound absorption and addresses the challenges of meeting or exceeding both acoustical targets and weight reduction targets for all vehicle types – including steel, aluminum or composite bodies with internal combustion, hybrid, or electric engines. HPAM is suitable for acoustic control in all types of appliances, automobiles, and even large trucks and farm vehicles. For environmentally conscious industries, HPAM is made with 100% recyclable polypropylene.

Our Validation Guide is available on request.

Critical Properties

- Material: 100% Recyclable PP

- Thickness Range (mm): 11.5 – 27.0

- Weight Range (gsf): 16.0 – 50.0

- Weight Range (gsm): 172 – 538

Characteristics

HPAM is highly compressible allowing for use in cavities with varying thickness. Lower thickness allows for optimized packaging for smaller spaces.

May be die cut with existing equipment – no tooling or equipment modifications are necessary.

Die cut parts can have a perimeter seal to encapsulate loose fibers and eliminate product degradation. Because of the unique construction, you can layer and die cut four parts at a time.

Automotive Applications

Insulators

- Door panels

- Pillar trim

- Center console

- Instrument panel

- Rear quarter panel

- Rear under seat

- SUV liftgate

- Dissipative dash

Acoustical Pads

- Headliner

- Trunk trim

- Package tray

Eco-Attributes

Constructed with 100 percent virgin polypropylene, HPAM is lighter than competitive products – critical for fuel economy, and it is fully recyclable at the end of its useful life. HPAM is is made with 100 percent renewable electricity through the purchase of Green-e certified renewable energy (RECs).

No PFAS is intentionally added in products or processes at MNW.

Build a Better World

You play a vital role when you choose our eco-friendly nonwovens. Explore the positive contributions to energy conservation, air quality, water preservation, and waste reduction.

Related Products

Request More Information

"*" indicates required fields